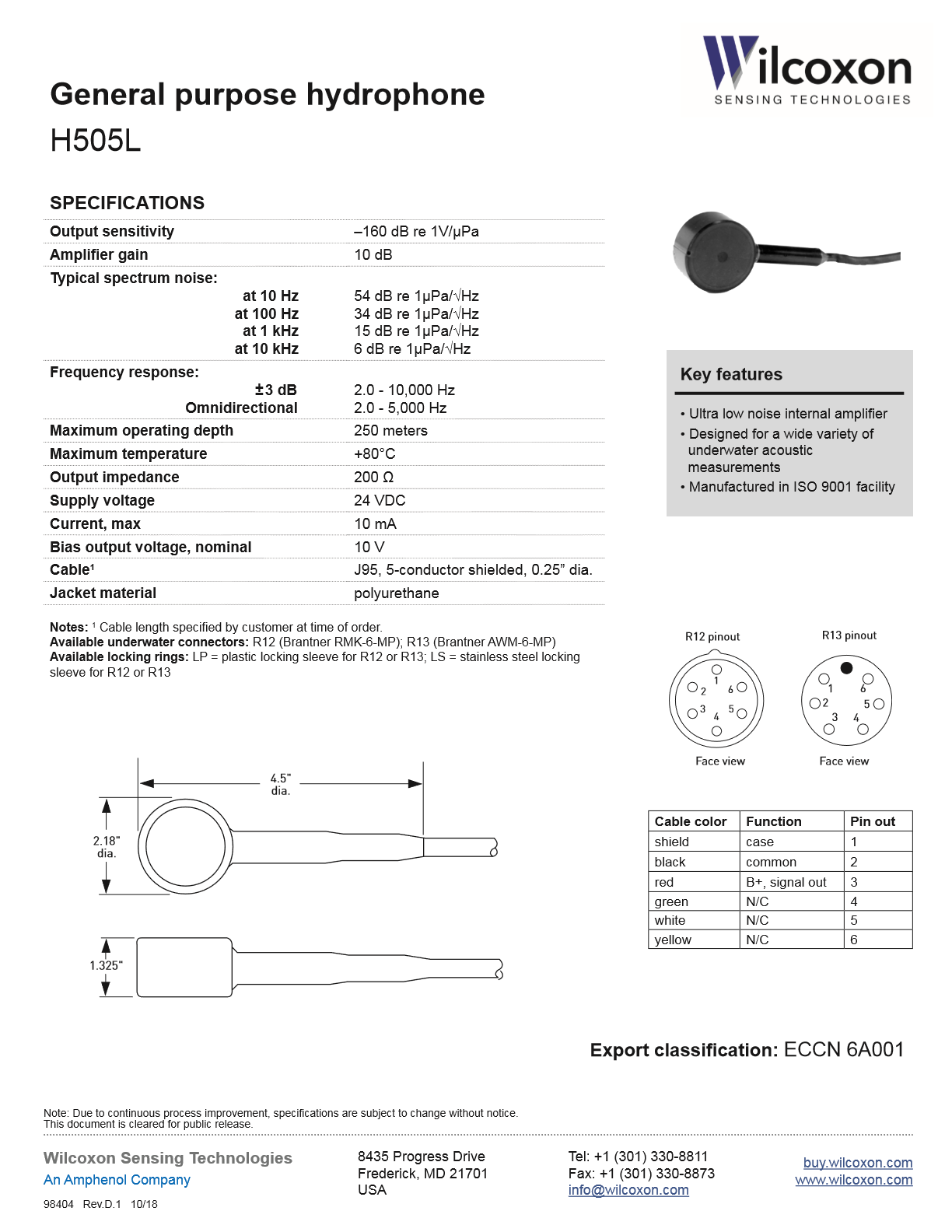

The H505L hydrophone is designed as a small, versatile, self-amplified hydrophone for use in a wide variety of underwater acoustic measurements. Ruggedness, low cost and an ultra low-noise internal amplifier are prime features of this model. The internal amplifier eliminates triboelectric cable noise, connector contamination problems and the requirement for an expensive in-line amplifier. The hydrophone and cable entry are completely encapsulated in polyurethane, preventing water intrusion caused by cathodic action. The assembly uses preaged piezoelectric (PZT) sensing elements.

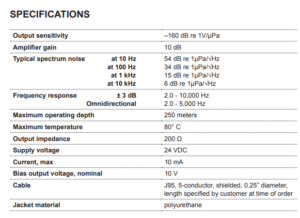

Sensitivity tolerance: -160.0 dB re 1V/µPa

Low frequency: 2.0 Hz (120 CPM)

High frequency: 10.0 kHz (600 kCPM)

Maximum temperature: 80°C

Designed to military specifications

Features:

| Phone | 303-279-7797 |

|---|---|

| TollFree | 800-279-7796 |

| Fax | 303-278-9909 |

| Address | 1075 S Yukon St, Suite 100 Lakewood, CO 80226 |

Stay connected! Subscribe to our newsletter to stay up to date with all the latest products.