The requirements for the supply of filtered, lubricating coolants to machine tools vary to a large degree. They require different pump solutions: small and compact pumps for external cooling, centrifugal pumps with closed impellers for medium-pressure applications or high pressure pumps based on screw spindle technology for internally cooled tools. They must either be designed exactly for a specific working point or controlled by a variable frequency drive.

Immersion Pumps TS

Immersion Pumps (S)TC

Immersion Pumps (S)TH

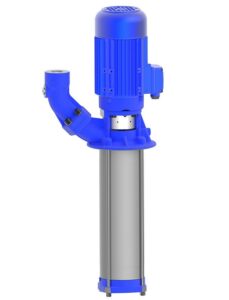

Pressure Boosting Pumps FH

Screw spindle pumps BFS | TFS | FFS

| Phone | 303-279-7797 |

|---|---|

| TollFree | 800-279-7796 |

| Fax | 303-278-9909 |

| Address | 1075 S Yukon St, Suite 100 Lakewood, CO 80226 |

Stay connected! Subscribe to our newsletter to stay up to date with all the latest products.